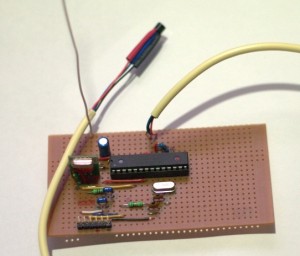

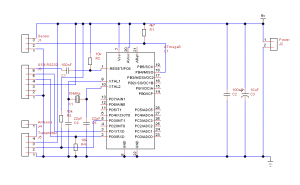

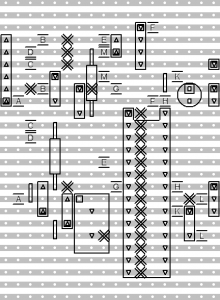

After learning how to use VeeCAD and TinyCAD, I’ve got a layout, and I start the rather tedious process of cutting tracks (with a hand-held drillbit – I don’t happen to own a drill press… yet), then soldering the jumper wires, then the passive components, then measuring resistance here there and everywhere to make sure I don’t have bridged joints etc before finally attaching the chip and transmitter module – and I end up with this:

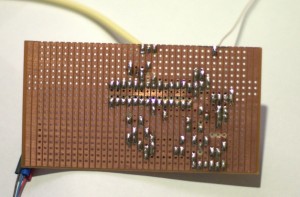

And now I need to test it in the outside world, so a 9V battery and 78L05 regulator later, plus an “enclosure”:

I stick it in the fork of a tree in the back garden, and go back inside to try it out.

First indications are not particularly encouraging – while my “U U U U U U U U ” sync header seems to be working reasonably well, only about every 5th message is actually making it back to the receiver uncorrupted. Still, I hack together a very quick python script to pull out the data (which does have a checksum), and then I move the receiver (still on breadboard) from the workstation to the server at the other side of the office.

And then discover something amazing – the noise has all vanished, and all my messages are coming through clean and clear with no garbage between transmissions! Something on my desk must be producing a reasonable amount of noise around 315MHz – my guess is it would have to be one of the monitors. Whatever, my noise problems are now basically solved, and the server is getting data!